Me-Sep is an innovative research and engineering company specializing in membrane technology. We provide technical solutions for researchers and engineers, with a focus on lab and pilot scale projects. Our team of specialists designs and manufactures custom-made machines for the membrane industry, supporting businesses in technology transfer for membrane production, module manufacturing, and construction of separation systems. For our customers, we offer support in technology transfer for flat sheet and hollow fiber membrane production, membrane module manufacturing, and construction of separation systems for gas and liquid mixtures. Me-Sep team specializes in capillary/hollow fiber membrane spinning for UF/MF/NF applications, TFC coating on flat sheet and capillary membranes, development of spinning, casting, and coating equipment, QC tests, and filter potting systems.

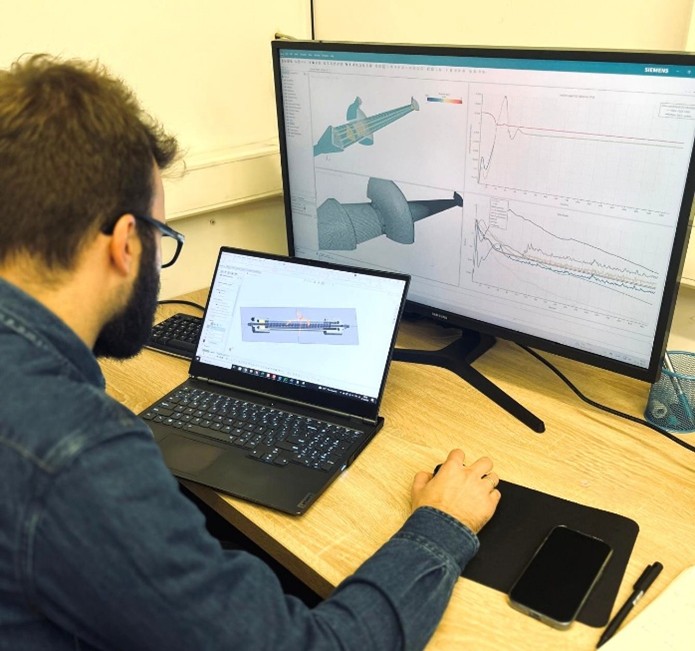

Computational Fluid Dynamics (CFD) Workstation

The CFD Workstation equipped with Siemens STAR-CCM+ software is dedicated to the development and analysis of computational fluid dynamics (CFD) models for membrane modules (Task 7.2). It supports the iterative design and optimization of module configurations, enabling accurate prediction of flow dynamics, mass transport, and overall performance under various operating conditions. Key activities include defining model parameters, selecting appropriate physicochemical properties and governing equations, developing the computational mesh, and parameterizing the model based on empirical data. Sensitivity analyses are performed to assess model behavior, refine predictive accuracy, and validate results against experimental observations.

Research and Development Lab

The ME-SEP Laboratory is dedicated to the research, development, and characterization of membranes and membrane modules. It synthesizes flat-sheet and capillary membranes for a broad range of applications, including water purification, gas separation, hydrogen technologies, and biotechnological processes. The laboratory designs, produces, and assembles membrane modules for testing and pilot-scale implementation, while performing comprehensive material and process characterization to assess physicochemical properties, flow behavior, and filtration efficiency under controlled conditions. It also plays an active role in developing and optimizing specialized equipment for membrane fabrication and testing. By integrating experimental research with applied technology development, the ME-SEP Laboratory advances the optimization of membranes and membrane-based processes, enabling the delivery of innovative and high-performance solutions for both industrial and research applications.

ME-SEP personnel

Szymon Dutczak - Membrane technology specialist with over 20 years of experience in R&D, industrial applications, and process design

Co-owner and CEO of ME-SEP, he oversees the synthesis of flat-sheet and capillary membranes, the production of membrane modules, and the design of equipment for membrane fabrication and characterization. He brings extensive expertise in water purification, gas separation, hydrogen technologies, and biotechnological processes, acquired through positions at leading research institutions and companies such as the University of Twente, Gambro/Baxter, and the B. Braun Group. He has authored numerous scientific publications and holds several patents in the field. In his current role, he manages multiple research and implementation projects, ensuring their effective execution and timely completion. Within this project, he leverages his expertise to drive its successful realization.

Krzysztof Trzaskuś - Experienced membrane technology specialist and leader in R&D and industrial applications.

Co-owner, Vice President, and Chief Technical Officer at ME-SEP, he is a specialist in membrane technology with over 14 years of experience. His expertise encompasses the production of capillary membranes, the manufacturing of membrane modules, and the design of machinery and equipment for membrane fabrication and characterization. His work covers a broad spectrum of applications, including water purification, gas separation, membrane contactors, hydrogen technologies, and biotechnological processes. He has authored numerous scientific publications and patents and serves as manager and contractor for several research and implementation projects. Within the project, he oversees the proper execution of research activities, ensuring their quality and alignment with project goals.

Michał Chwaluk - Mechanical engineer with expertise in machine design and computational modelling for membrane process technologies

Head of the Engineering Department at ME-SEP, he is a mechanical engineer specializing in machine design. He is responsible for developing equipment for membrane production and overseeing their manufacturing processes. Within the project, he focuses on the development and refinement of the CFD model of the membrane module. His responsibilities include defining the module geometry and flow boundaries, creating and optimizing the computational mesh, parameterizing the model, and simulating flow and mass transport phenomena. He identifies critical points, analyzes velocity, pressure, and concentration distributions, and validates the model against experimental data to enable iterative optimization and improve overall module performance.

Arkadiusz Knapik - Chemist with a PhD specializing in heterogeneous catalysis and instrumental analysis, leading R&D activities in membrane technology and photochemical reactor design

Head of the Research and Development Department and Process Technologist at ME-SEP, he leads the company’s research and development efforts in membrane production technologies. Within the project, he contributes as a supporting researcher, focusing on the design, construction, and optimization of advanced photo-membrane chemical reactors capable of conducting light-induced reactions under precisely controlled process conditions. His expertise lies at the intersection of catalytic system design and materials engineering, enabling the effective integration of photochemical and membrane-based processes for enhanced performance and efficiency.

Patrycja Turalska - Project manager with strong expertise in research coordination, financial oversight, and dissemination of EU-funded projects

Head of the Operations and Project Management Department at ME-SEP, she oversees the comprehensive implementation of both research and organizational activities within the project. She is responsible for monitoring research and administrative progress, preparing financial reports, and ensuring that all activities adhere to the project’s timeline, budget, and European Union requirements. She also supports the project coordinator in reporting processes and strengthens the project’s visibility through effective dissemination via the ME-SEP website, social media channels, publications, and participation in scientific and industry events.